The metal casting market is continually evolving, pushed with the demand for higher precision, enhanced quality, and reduced defects. In this landscape, the strain casting device plays a crucial purpose. nevertheless, for probably the most demanding apps, a specialized variety of casting equipment is needed: the vacuum strain casting equipment. this information explores the unique advantages of these machines, focusing on how they greatly enhance the accuracy and top quality of metal casting, especially for valuable metals like gold and platinum.

Table of contents:

some great benefits of working with Vacuum strain Casting equipment for top-excellent success

How Vacuum stress Casting boosts the Accuracy of Gold, Platinum, along with other Metals

Why Vacuum Pressure Casting is Essential for superior-Precision Industries

The Advantages of Using Vacuum strain Casting devices for top-high-quality outcomes

Vacuum stress casting devices give an important breakthrough as compared to conventional casting strategies. The core gain lies inside the elimination of air pockets and gas porosity within the casting. By carrying out the casting procedure below a vacuum, the molten metal is allowed to move far more freely and fully fill the mold cavity. This leads to denser, stronger castings with less inner defects. In addition, the applying of stress in the course of the solidification section helps to further more consolidate the metallic, reducing shrinkage and increasing the general high-quality. This tends to make vacuum tension casting ideal for generating intricate and complex styles in which even the smallest imperfections can compromise the features or aesthetic appeal of the ultimate merchandise.

How Vacuum Pressure Casting Enhances the Accuracy of Gold, Platinum, along with other Metals

The superior worth and exclusive properties of treasured metals like gold and platinum necessitate Outstanding casting precision. Vacuum gold casting device know-how is specifically made to satisfy these demanding specifications. The vacuum natural environment not merely prevents oxidation with the molten metallic but additionally guarantees a thoroughly clean and steady casting procedure. This is especially vital for gold, which can easily tarnish or develop floor defects if subjected to air in the course of casting. What's more, the controlled pressure utilized in the course of solidification promotes uniform grain structure and minimizes the potential risk of cracking or distortion. This brings about castings that are dimensionally precise, have fantastic area finish, and keep the specified mechanical Attributes.

Why Vacuum Pressure Casting is Essential for significant-Precision Industries

superior-precision industries, for example aerospace, medical device manufacturing, and significant-conclude jewellery creation, depend upon vacuum tension casting to accomplish the stringent top quality expectations demanded for his or her apps. the chance to develop castings with limited tolerances, negligible defects, and reliable materials properties is paramount in these sectors. such as, in the aerospace field, vacuum pressure Forged elements are used in important engine sections the place dependability and performance are non-negotiable. in the same way, in professional medical unit producing, vacuum pressure casting assures the biocompatibility and structural integrity of implants. the advantages lengthen to jewellery making too, in which intricate types and flawless finishes are essential for producing significant-value parts. Ultimately, vacuum pressure casting provides the required control and precision to satisfy the demanding necessities of such industries. As pressure casting machine evidenced by goods similar to the TAKJ-VC-W readily available at https://taeantech.com/products/takj-vc-w, these machines are specially made to cater on the precision desired by vacuum strain casting processes.

In summary, vacuum pressure casting equipment are indispensable equipment for achieving superior precision and remarkable top quality in metal casting. The mix of vacuum surroundings and controlled strain eliminates common casting defects, improves product Homes, and makes sure dimensional precision. For industries demanding the best amounts of efficiency and dependability, purchasing vacuum stress casting technological innovation is not only a preference but a requirement. look at the particular prerequisites of your software and investigate the assorted vacuum stress casting remedies available to unlock new choices in steel casting and elevate the quality of your last products.

Jonathan Taylor Thomas Then & Now!

Jonathan Taylor Thomas Then & Now! Danny Pintauro Then & Now!

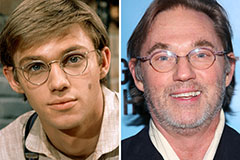

Danny Pintauro Then & Now! Richard Thomas Then & Now!

Richard Thomas Then & Now! Katey Sagal Then & Now!

Katey Sagal Then & Now! The Olsen Twins Then & Now!

The Olsen Twins Then & Now!